-

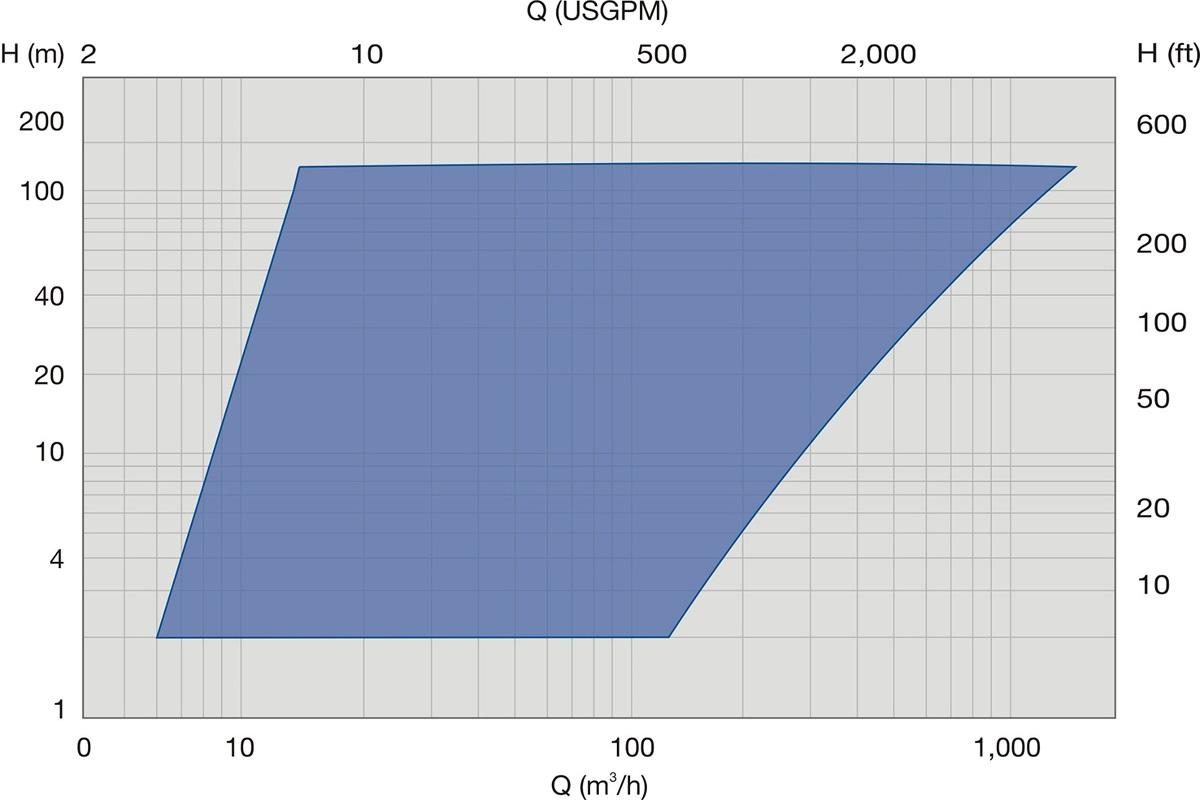

SNS end-suction single-stage process pump rangeThe SNS end-suction pump has been designed to exceed the highest energy efficiency regulations across all industries and also the design requirements of ISO 5199 international standard. The innovative design makes this centrifugal pump more reliable while significantly reducing total cost of ownership.

Reliable SNS process pump for dewatering applications

Sulzer SNS pump improves pumping efficiency in mine dewatering

The customer had made a survey of the total cost of ownership (TCO) in mine dewatering processes. Consequently, Sulzer was asked to offer a pump with the highest available efficiency for the given applications. The Sulzer SNS process pump was considered to have the highest efficiency in the design conditions. The innovative and rigid construction of the SNS pump also made it possible to run the pump in partial load conditions, which was mandatory for the application. The offered SNS pump was equipped with a variable speed drive like the old slurry pumps.

The challenge

The pump was required to pump clarified water from the mine. The water load in the mine varies and therefore two of the three existing slurry pumps often needed to be used. The customer required reliability, small need for maintenance, high energy efficiency and a robust design. The pump needed to handle a wide operating range with high efficiency.

The solution

Sulzer delivered the new SNS4-50 process pump made of stainless steel in the spring 2015. According to the customer, they were surprised about the low energy consumption and the low noise level. They also realized that the SNS pump can drain the settling pit on its own, whereas the old slurry pumps suffered heavy cavitation with low suction heads. Even with a partial load the SNS pump was more efficient than the slurry pumps at their best efficiency point.

The SNS process pump is optimized for water, fibers and chemicals pumping. Therefore, it is significantly more efficient than slurry pumps.

Toni Heikkilä

Sales Manager, Sulzer Pumps Finland Oy

Customer benefits

- The customer made an energy consumption study by each cubic meter pumped. The SNS pump was found to be more than 0.2 kWh/m³ below the old slurry pumps. According to the customer this gives them a direct annual energy saving of EUR 24'000 per pump.

- The payback time of the pump investment was very short.

- The customer tested the old pump and the SNS4-50 pump. The result shows that the SNS pump has a higher efficiency at 30% BEP than the old ones at 100% BEP.

- The customer was clearly satisfied with the solution and considers replacing the existing slurry pumps for clarified water with SNS process pumps to improve the total pumping efficiency.

- The SNS process pump proved to be reliable in the mine dewatering application. The pump has been in continuous operation for a year without any signs of reduced efficiency by wear or a single malfunction.

- The low NPSHr of the SNS pump enables the customer to run the clarifier with lower levels, giving more reserve for water.

The Sulzer difference

- Highest efficiency in the process pump range

- Highest hydraulic power in the process pump range

- Low energy consumption due to high efficiency

- Direct annual energy saving EUR 24,000 per SNS pump

- Short payback time

- Heavy duty bearing construction

- Low spare part costs due to high standardization

- Low installation and maintenance costs

Sulzer SNS4-50 end suction single stage pump

| Pump | SNS4-50 |

| Type | Centrifugal end suction pump |

| Impeller | Open |

| Material | Duplex stainless steel A890 Grade 3A |

| Seal | Single mechanical |

Mine dewatering with Sulzer SNS pump

| Capacity | 210 m³/h |

| Head | 130 m |

| Liquid | Mine water |

| pH | 8 |

| Temperature | 30°C |

| Density | 0.998 kg/dm |