Pump retrofits increase performance and reduce costs

Major Middle East oil company upgrades 15 salt water disposal pumps with Sulzer expertise

The demand for products derived from oil and gas continues and companies involved in the extraction and refining of these products need to maintain their competitive edge. Optimizing production efficiency and minimizing costs helps these businesses to continue to deliver cost-effective products to the market.

Challenging times

However, in this case, the upstream process was facing challenges associated with the maturity of the field. Oil pressure was dropping and this meant that the water volume being injected into the field needed to be increased. As a result, this would raise the amount of water that has to be separated from the oil and gas that is brought to the surface.

The upgrade project identified 15 SWDPs, whose capacity needed to be increased from 55 million bpd to 75 million bpd, while keeping the delivered head the same. The pumps are arranged in five trains of three BB5 pumps with 12 supplied by one original equipment manufacturer (OEM) and the fourth train supplied by another.

Evaluating the options

Several options were investigated by the operator, including a huge capital expenditure of replacing the pumps with new assets. They decided the best option was to issue a competitive tender between the two pump OEMs and, aware of Sulzer’s retrofit capabilities, to include this as a third possibility.

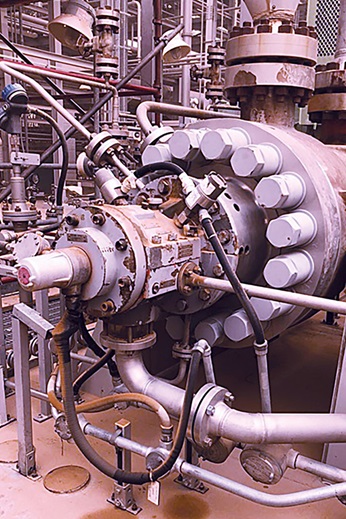

Sulzer’s proposal was to retrofit all 15 pumps with the company’s GSG pump cartridge while retaining the original pump barrel casings, drive motors and the surrounding infrastructure. The existing motors driving these pumps had been originally designed to deliver additional power and would therefore be capable of delivering the increased capacity without changes.

This solution offered significant benefits by delivering the increase in performance while retaining all the site critical interfaces and reusing the existing lube oil systems as well as mechanical seal ancillaries. It also provided the same cartridge for both designs of pump, allowing interchangeability of spare parts between all the units and reducing the amount of spares stock holding.

Long-term success

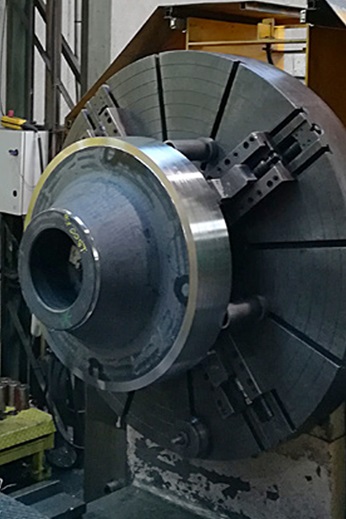

Phase 1 of the project was awarded to Sulzer and eight pumps were identified for the retrofit. The new GSG hydraulics were fitted with a minor modification, all designed and built in Sulzer’s specialist manufacturing facility in Germany. A new barrel was produced as part of the project so that all the new cartridges could be tested in-house before being installed onsite.

The customer has a high level of confidence in Sulzer’s engineering expertise. The retrofit project has been very successful and has not impacted on normal operations because of the effective process of reusing the existing barrels and replacing the cartridges.

Luca Lonoce

Pump Services Retrofit Sales Director at Sulzer

As a result of the success of phase 1 of the project and the proven performance of the new barrels, the operator approved phase 2, the retrofitting of the remaining seven pumps.

Luca concludes: “The technical experience and manufacturing expertise at Sulzer has enabled the pumps to not only meet the new performance levels, but also extend their operational life and improve their reliability. This cost-effective solution has also reduced capital expenditure and reduced the projected energy costs over the next 20 years.”