-

Submersible grinder pump type ABS PiranhaPiranha sewage pumps with shredding action provide reliable and economical discharge of effluent under pressure in private municipal and communal schemes.

Pressurized dewatering

The economical solution for wastewater disposal problems

The challenge

Recent EU regulations (EU directive 91/271/EEC and European Water Framework Directive) have resulted in restrictions in the usage of septic tanks and mini-treatment systems in domestic sewage and wastewater applications. Therefore, the sewage must be pumped to the local wastewater treatment plant, and this can be several kilometers away.The solution

Pressurized dewatering is a very effective solution for removing wastewater in difficult terrain where it is difficult to lay gravity pipes. The pressurized dewatering method of sewage removal has proved very popular in many European countries. 100% of domestic dwellings in Holland, a good example of very flat terrain, have been connected to a central sewage system, and the vast majority is connected via pressurized lines.Pressure or grinder pump systems utilize a small grinder pump station at each wastewater or sewage source. Small-diameter low pressure sewer lines are used for the transmission of the sewage. This is either pumped to a terminal pumping station or directly to a wastewater treatment plant. Wastewater from the residence or business is collected in small underground grinder pump stations. Stations serving single residential units typically utilize plastic sumps of some 700 mm to 1.2 m in diameter.

Customer benefit

The main benefit with this approach is that outlying areas can be developed for housing, and limitations of population around an existing gravity line can be avoided. In comparison to the conventional gravity sewer line, there is also considerable cost saving with regard to the size of trench required and the size of the pipework. A two inch pipeline will occupy just 26% of the volume required by a four inch pipeline, and will also not need to be buried so deep underground.

The volume of sewage remaining in the pipeline per meter, when the pump is not running, is also much lower, at 34% of the four inch equivalent line. This in turn considerably reduces the possibility of septicity. Studies have also shown that pressure sewers can be up to 50% cheaper than equivalent gravity lines. Since the line is closed, there is no infiltration or excess inflow caused by broken pipes or leaky joints, which can potentially result in a reduction of inflow to the treatment plant.

The grinder pumps used typically range from 1.3 to 2.6 kW, depending on the flow rate required, and the number of residents or houses served by the pump station. All solids in the discharged waste are ground into slurry and pumped through small-diameter (32-50 mm) pressure sewer lines. Since these systems do not rely on gravity, the sewers can be constructed at minimum depth below ground, from 0.5 to 1 m, causing less civil disruption and avoiding major earth removal work.

Jim Rossiter, Technical Support Manager - Sulzer Pump Solutions Ireland Ltd.

“These pump stations are available in packaged, easily serviceable, economical units. They are unobtrusive and blend into the surroundings, leaving only a very small footprint.

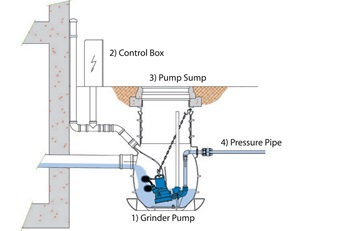

The main components of the sewer systems

1) Submersible grinder pumpThe shredder pumps macerate the sewage/wastewater mixture to fine slurry to enable it to be pumped through small-diameter pipelines (32-50 mm) and over long distances, up to 3 km. Seal monitoring and thermal protection is also available. The Sulzer macerator pump is the best on the market.

2) Control box

The control box switches the pump on and off through a series of float switches located at different levels inside the pump sump. Most units will have an external warning mechanism, usually a flashing light or a horn. Advanced units can use telemetry.

3) Pump sump

The pump sump is the collection point for the waste from the domestic or industrial unit. The pump is mounted inside on a guide rail assembly that allows the pump to be easily removed for service. The sump is made from LDPE (Low Density Poly Ethylene) and fitted with an anti-floatation device. One or two pumps can be fitted into the tank depending on the flow rate requirement.

4) Pressure pipe

The pipe, usually made of plastic (PVC or HDPE), can be laid using a small digger and is typically 32 or 50 mm in diameter. It is normally laid along the roadside and to a depth of 0.5 to 1 m. Horizontal directional drilling (HDD) can be used to lay the pipe long distances underground.