-

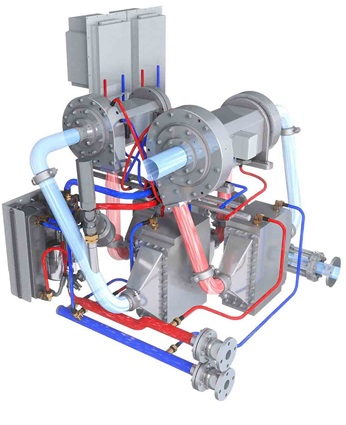

HSR turbocompressorThe HSR turbocompressor does not wear and provides oil-free air with the greatest reliability. Used primarily in plant compressed air supply, as it includes high-speed permanent magnet motors and magnetic bearings, this totally oil-free turbocompressor will minimize the life cycle cost.

HSR turbocompressor for truly oil-free air

Sustainable food production with oil-free turbocompressors

The challenge

In the meat factory, 8 bar compressed air is widely used for pneumatic tools, control of instruments, activation of pneumatic components and valves, etc. Some compressed air also comes directly in contact with the food. Therefore, it must be clean, oil-free, dry and odorless. This quality could not be 100% guaranteed with the oil-lubricated screw compressors initially installed on site, even with appropriate air-oil separators and oil filters. In addition, the screw compressors proved to be maintenance-costly as they required regular replacement of numerous wearing parts and frequent change of expensive food-grade oil. Considering these major drawbacks, the client decided to replace one screw compressor by a high-speed turbocompressor in 2016.The solution

During the first discussions, the client became highly interested in the high-speed turbocompressors, but wanted some testing in real conditions to validate all promised advantages. Therefore, a turbocompressor installed in a container was brought to the site and started to run in replacement of an installed screw compressor. These tests were the perfect foundation for a fruitful partnership. After having run for one year without any maintenance, the turbocompressor proved to deliver 100% oil-free air with remarkable efficiency even at partial loads. Moreover, the ease of use of the machine and its low noise level convinced the client that the turbocompressor fitted his needs exactly. The high-speed turbocompressor was finally placed permanently in the main compressor room.A piece of meat with peace of mind. With its absolutely oil-free design, the HSR high-speed turbocompressor eliminates all risks of compressed air contamination.

Saku Vanhala

Product Portfolio Manager

Customer benefit

The high-speed turbocompressor has digitally controlled magnetic bearings which work without physical contact between rotating and stationary elements. There is no mechanical friction whatsoever. This gives the client three major advantages:

- No need for lubrication. No single drop of oil in the machine ultimately means no threat to food product safety.

- No parts to wear. No gears, bearings, seals, etc. to replace regularly. Except for changing the air filters when clogged, the machine is maintenance free.

- No risk of failure. Parts that don’t wear don’t fail. The machine is extremely reliable, and unplanned stops which could affect the whole production process do not occur.

The turbocompressor is equipped with an integrated variable speed drive which controls the motor speed – based on actual air demand – and maintains a constant air pressure. The unit is highly flexible and perfectly adapts to ever-changing conditions at the client’s site.

The turbocompressor has high-speed motors and directly-driven titanium impellers rotating at up to 35’000 rpm. This ensures an optimal wire-to-air efficiency. 90% of the heat produced during successive compression stages is recovered with an advanced liquid cooling system, and can be re-used by the client for various heating processes in the plant.

The high-speed turbocompressor has now run in the meat factory for more than 3 years with no maintenance. It has proven to be highly efficient and reliable with lower total cost of ownership compared to the initially installed screw compressors. The client is extremely satisfied with the equipment and collaboration and will order a second high-speed turbocompressor during 2019.

Turbocompressor HSR 185-201.020.1013

| Volume flow | 28 m³/mn |

| Pressure | 8 bar g |

| Input power | 200 kW |

| Input voltage | 400 V ± 10% |

| Input frequency | 50 Hz |

| Number of compression stages | 3 |

| Max. noise level | 79 dB |

| Dimensions | 1820 x 1980 x 2056 mm |