- Enhancing column performance

Column internals

Optimizing performance of columns

- Liquid distributors

- Liquid collectors

- Support and locating grids

- Gas inlet systems

- Liquid inlet systems

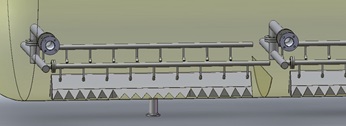

Liquid distributors

Liquid distribution is crucial for packed bed performance. We offer a wide range of liquid distributors for different applications. Specific distributors are available for:

- Liquid loads of 0.02 m3/m2h up to 400 m3/m2h

- High turndown rates

- Distributors for high loaded columns requiring optimized separation of liquid and vapor and low pressure drop

- Distributors for suspensions, emulsions, fouling or contaminated liquids

- Distributors for moving conditions

Vapor distribution

The distribution of vapor is less critical than that of liquid, but is nevertheless challenging for the design of good vapor distributers. Our experienced engineers rely on decades of expertise implemented in internal design tools, and are supported by cutting-edge technologies such as Computational Fluid Dynamics (CFD).

Collecting devices

Liquid collectors with integrated packing support help to save column height. Optimized design of the collecting troughs reduces pressure head in the collecting section. Chimney trays are provided to accumulate liquid and redistribute it, or to improve vapor distribution below packed beds.

Flash feed systems

Flashing feed has to be separated in or outside the column before liquid and vapor are distributed individually. Different feed conditions are carefully considered in the design of the flash devices.

Liquid inlet systems

Depending on the flow rate, an appropriate inlet system is recommended. We offer solutions to feed separation trays and liquid distributors.

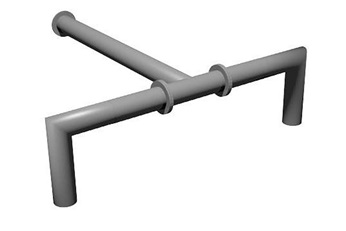

Sand jetting system

Sand jetting system consists of a distributor pipe system with multiple jet nozzles and a sand pan at the center. While solids accumulate in the bottom of the vessels, the sand jetting system will fluidize the solids and remove them from the vessel. The sand jetting technology from Sulzer completes the portfolio for separators.

Product applications

Sand jetting systems are widely used in the upstream industry. The most particularly suitable used conditions are:

- Slug catchers

- Production separators

- Electrostatic desalters

Support and locating devices

Support systems are available for every different packing type. They can be easily installed with a minimum of beams and welding attachments. Beside welded constructions, clickable solutions that save installation time are also available. Locating devices can be partly integrated into the liquid distributors to save height and installation time.

Contact our Separation technology team directly