- Centerline mounting to allow free thermal expansion and high nozzle loads

- Minimum bearing span to minimize shaft deflection

- Single cover casing design to reduce overhaul times

- Carbon steel or chrome steel casing with excellent mechanical properties

- Double mechanical seal provides safer operation

HZB-HTF double suction volute pump

Helping you handle hazardous liquids

The HZB-HTF is a horizontal, radially split, single stage, double suction centerline mounted pump. The HZB-HTF are ideal for use in thermal oil applications for handling clean hot and hazardous liquids.

- Main heat transfer fluid (HTF) circulation in concentrated solar power stations

Main design features

- Double suction impeller with staggered vanes for low Net Positive Suction Head required (NPSHR) and low-pressure pulsations

- Different nozzle positions are possible

- Amply sized sleeve radial and tilting pad bearings with forced lubrication as standard

- Optional self-contained oil lubricated bearings

- Stiff shaft ensures that critical speed is a minimum of 20 % above the maximum operating speed

- Mechanical seal jacket cooling

Key characteristics

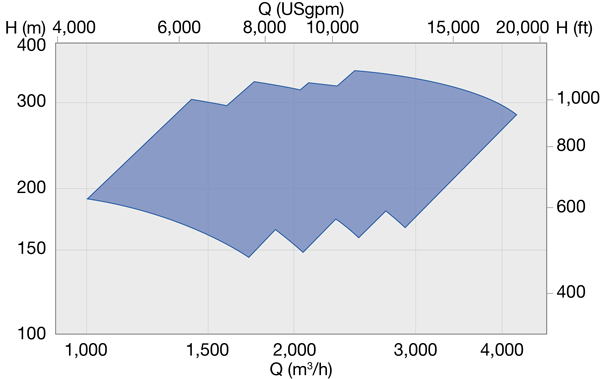

| Capacities | Up to 4,000 m3/h / 17,500 US gpm |

| Heads | Up to 340 m / 1,115 ft |

| Pressures | Up to 48 bar / 700 psi |

| Temperatures | Up to 425°C / 800°F |

| Discharge sizes | Up to 400 mm / 16 inches |

Performance range

Performance range 50 and 60 Hz